How can we help you

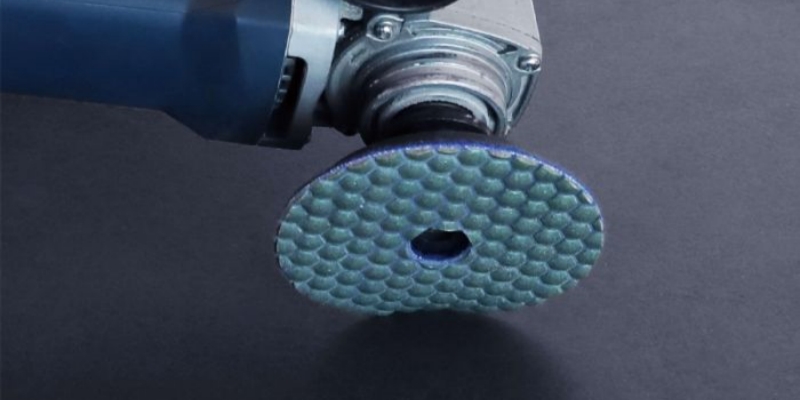

Achieving a perfect, high-gloss finish largely depends on selecting the appropriate diamond polishing pad. Whether working with concrete, marble, or granite, the type of pad, its grit level, and bonding directly affect both performance and the quality of the finish. Picking the right polishing pad isn’t just about speed or ease—it’s about ensuring the surface is polished evenly, efficiently, and with durable results.

Understanding Material Compatibility

The first step in choosing the right diamond polishing pad is to understand the material you’re working on. Different surfaces require specific pad features to get the best results. For instance, hard materials like granite or concrete need a more aggressive pad that can withstand strong friction without wearing out too quickly, while softer stones such as marble require a pad that offers gentle yet consistent polishing. A flexible wet polishing pad is ideal for delicate surfaces, using water lubrication to reduce heat buildup and enhance shine.

Considering the Polishing Stages

Polishing typically involves several stages, starting with coarse grinding and moving toward fine polishing. For those seeking simplicity and efficiency, 3 step dry polishing pads provide a convenient option by combining multiple grit levels into three stages, saving time and effort. These pads are especially useful when water use is limited or a quick turnaround is necessary. Selecting the correct grit progression ensures the surface smoothly transitions from a matte look to a mirror-like gloss without swirl marks or uneven areas.

Flexibility and Shape for Complex Areas

Not all surfaces are flat or easy to access. Countertops, edges, and decorative corners often need a polishing pad that can conform to different shapes. In these cases, triangular flexible polishing pads offer excellent maneuverability, enabling users to reach tight spots and maintain consistent pressure throughout polishing. Their flexibility helps achieve an even finish on curved or irregular surfaces where rigid pads might not work well.

Matching Pads to Equipment and Application

Lastly, make sure your polishing pads are compatible with your grinder or polisher. Pads come with various attachment types—such as Velcro, hook-and-loop, or backer plate systems—and using the right one enhances stability and performance. Also, consider whether your project requires wet or dry polishing. Wet polishing reduces dust and prolongs pad life, while dry polishing provides greater mobility and convenience in places where water isn’t available.

Choosing the right diamond polishing pad is essential for professional-quality results. By aligning the pad type, flexibility, and grit sequence with the surface and project needs, you’ll improve the final finish and extend your tools’ lifespan—ensuring every project achieves the precision and brilliance you desire.