How can we help you

Traditional diamond powder can be divided into two categories, polycrystalline diamond powder and single crystal diamond powder. With the rapid development of nanotechnology, a new type has been independently developed among the original two major diamond like powders: nano diamond powder.

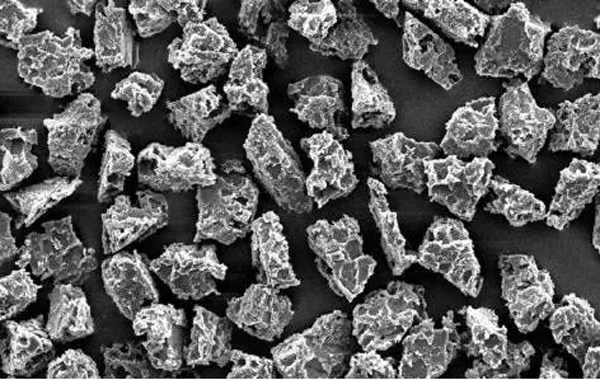

Polycrystalline diamond powder

Polycrystalline diamond is synthesized under the action of a transient strong shock wave formed by an explosion. It has high impact resistance and high bending strength. It not only has the hardness of super hard materials, but also has the extraordinary high strength and high toughness of nano materials. Its dual advantages constitute its unique physical properties, and it has important applications in high-tech industries and traditional pillar industries.

Uses: Mainly used in the fields of ultra-fine processing of chip optical crystals, ultra-precision polishing of large silicon wafers, surface modification, etc. The spherical polycrystalline diamond powder has a gray-black appearance with a slight metallic luster.

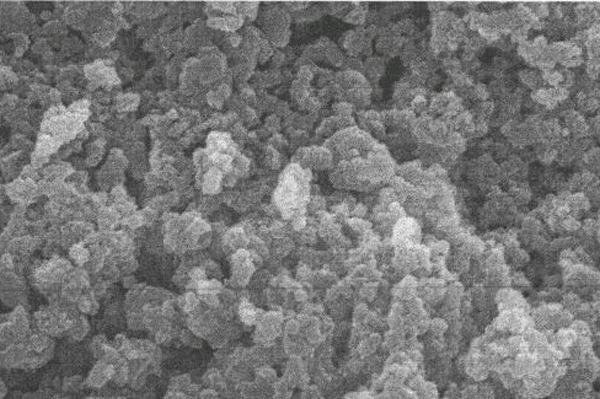

Single crystal diamond powder

The crystal shape of single crystal diamond powder is regular and complete hexa-octahedron, with high strength, toughness and good thermal stability, and strong impact resistance.

Uses: Suitable for the manufacture of electroplated products, grinding wheels, grinding wheels, for polishing and engraving of high-grade stone, processing of automotive glass, high-grade furniture, ceramics, cemented carbide, magnetic materials, etc.

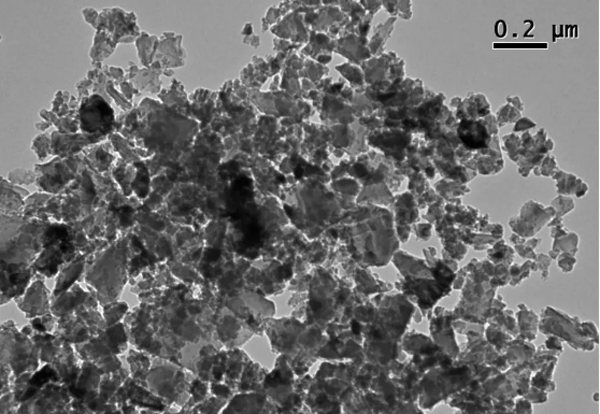

Nano diamond powder

Nano diamond powder not only has the inherent characteristics of diamond, but also has small size effect, large specific surface area effect, quantum size effect, etc, thus exhibiting the characteristics of nanomaterials. After different chemical treatments, a variety of different functional groups can be formed on the diamond surface. This diamond crystal has a high adsorption capacity.

Uses:1. Preparing advanced grinding paste and polishing liquid for ultra-fine processing of quartz, optical glass, semiconductor, alloy and metal surfaces.

2. Preparation of catalyst: Nano grade diamond and amorphous carbon have a large specific surface area, contain a variety of surface functional groups, and are very active. The preparation of catalysts can improve the activity data and promote the interaction of organic compounds.

3. Preparation of nano composite structural materials: composite nano diamonds with nano silicon powder, nano ceramics and various nano metals can produce new type nano structure materials. Because of their unique properties, they can be used to manufacture semiconductor devices, integrated circuit components and computer parts.

With the advancement of science and technology, diamonds of various materials have been applied to the production of grinding or polishing tools. In order to manufacture new and professional diamond tooling for concrete and terrazzo, TransGrind diamond tools attached a lot of importance to know market demanding, and make different formula accordingly, by this way, we provide our customers with most suitable and professional products.